By Lee Toy

By Lee Toy

Vol. 4 No.1 – Jan. – Feb. 1981

THE HOLIDAY TAKES IT’S TOLL

Sorry that this issue of Kite Flyer is so late but with Christmas and New Years it was a busy time for us all. Hope you all had a great holiday season and best for the New Year.

HEART ATTACK! HEART ATTACK!

No, don’t call 911. It’s only the multicolored fleet of Torn Henry designed and built Heart Kites flying above Marina Green. These kites are made from spinnaker cloth, framed with a birch dowell and fiber glass rods and fly in a large range of wind speeds. The Heart kite is approx. 40″ tall and 55″ wide and is collapsible. These kites are now being offered thru Kite Flyer for $16, postage paid. (Just in time for Valentine’s Dav)

KITE HOUSE OF THE AUGUST MOON (or Raymond Lee is at it again!)

As February approaches the Year of the Monkey makes way for the Year of the Rooster. Unlike the Solar Calendar whose zodiac symbols change from month to month, the Chinese calendar is based on the Lunar Calendar and runs on yearly cycles. February 5 1981 marks the beginning of the Chinese New Year – The Year of the Rooster. The following years were Year’s of the Rooster: 1969,1957, 1945,1933 etc. If you were born in any of these years you would be characterized by the Rooster sign.

Last year Mr. Lee made a Chinese New Year kite. It is of bamboo frame and a pained nylon cover.

It is made in two sections with the top section showing the 12 signs of the Chinese Zodiac and the second section indicating the traits of each of the signs. The two sections are mounted on a vertical spar and can be rotated so that the correct year and sign can be shown off.

The kite is basically a flat, bowed kite and flys with a unique Mr. Lee tail and I am sure he’ll have some sayings to be flying with it in the days to come.

If you want a peek of the kite, just come down to the Marina Green on almost any Sunday any you’ll find Mr. Lee near the monument in his baseball cap. If you ask him politely he’ll be more than happy to show you his kite if it isn’t up in the air already…

THE PETER (LYNN) PRINCIPLE,

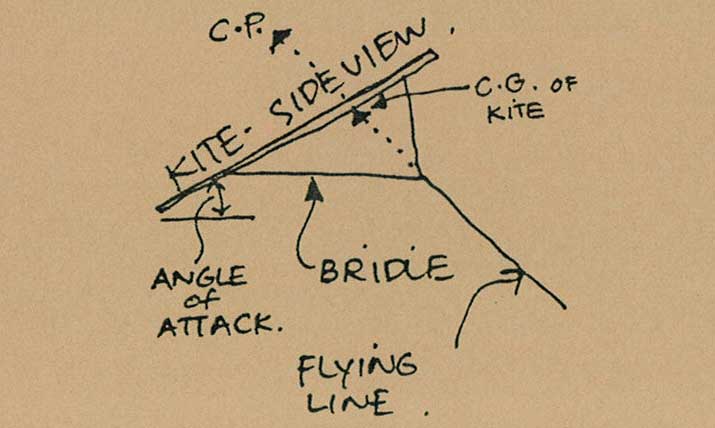

Someone once said that “if you bridled it correctly, you could fly a barn door’ Basically the bridle is the brains of a kite. It sets the ‘angle of attack’ at which a kite flies. After balance and symmetry it is the most important item on a kite.

Peter Lynn, kitemaker from New Zeland, said that if one can bridle a kite such that the center of pressure passes thru the center of gravity you should be able to make a kite fly. He was relating his theory to an experience he once had while in his early days of designing kites. He had designed a kite that flew and at the last moment changed one of the components withjout testing out the end results. What had once been a kite that flew nicely,now wouldn’t fly at all. A costly design change that eventually opened up some thoughts of the concept of Center of Pressure (C.P.) and Center of Gravity (C.G.). Since the change of the component only effected the C.G. and everything else remained the same Peter came to the conclusion that the two items were related. Being quite cognizent of his discovery he began to experiment.

In his experiments he tried changing the C.G. of his kites by adding a small weight to the nose or tail and adjusting the bridle. He found that by adding weight to the nose of the kite he could “solve” the problem of centering the C.P. and the C.G. of most of the kites he was having trouble with. It is this theory that we should consider when we end up with a “hanger” perhaps the solution can be found in PETER’S PRINCIPLE.

I tried out the theory with an Indian Fighter kite. Since it is a relatively simple kite, the things I was looking for were easy to find.

I must say that the kite is bridled empirically at about a 15-18% angle to the horizontal. It is this ‘angle of attack’ which is set by the bridle. and it is also the determing factor for where the center of pressure is to occur.

The center of gravity could be found simply by balancing the kite along it’s center spar until the kite balanced. I marked this on the face of the kite with a pencil. I then took a small “plumb” line and held the bridle (the bridle which was on the kite, and which I knew would be able to fly the kite on) and found the two points to intersect.

The theory should apply to most type of kites. I can see some exceptions in the Dragon kite configuration since the center of pressure would be affected by the presence of the tail. And also in kites that really need a tail to fly since the drag on a tail may be a much larger factor than its weight by itself.

One problem that I hope to look into is determining the C.G. of a parafoil this would have to be done geometrically adding all parts and then mathametically determining the location. If this can be done then the exact angles of the flares can be determined. Their angle would be such that the point of bridle would place the C.P. at the C.G.

I have one small parafoil that never flew very well and also a delta kite of George Ham’s earlier days to experiment on, and will let you know the results in the next issue.

FIBERGLASS ROD

Fiberglass rod is now available to interested kitemakers from a firm called ‘GLASFORMS’. Dave Beck is the man in charge of sales at:

GLASFORMS

271 Barnard Ave.

San Jose, CA 95125

(408) 297-9300

Glasforms supplies about 80-90% of the kitemakers using fiberglass rods in their kites.

Fiberglass rods are used in any kite form that uses a flexiable spar. Glasforms has the following sizes:

3/32″, 1/8″, 3/16″, 1/4″ diameter-lengths of up to 8′ can be shipped via UPS. No minimum order but there is a service charge of about $5.00 for any order less than $50.00. The company will cut to order your necessary length and you are only charged for what you actually get. The price per foot is about 9c.

The only problem I have with using fiberglass rod is the sliver problem. Whenever handling the fiberglass, one needs to be carefull not to run your fingers along the length of the rod because if you do you will experience a painful sensation in you finger tips. Generally the fiberglass you see in kites are ‘end grinded’ .

The only problem I have with using fiberglass is the “Slivers” that appear when handling the material. There are a number of precautions that can help prevent slivers but I generally end up getting some anyway.

In cutting fiberglass rod you can keep kite the following in mind for a clean cut:

1. Use a saw blade with a high number teeth / inch. An Exact saw blade works well on most diams.

2. Rotate the piece while cutting.

3. Place a piece of masking tape around the rod at the location to be cut and cut thru the tape

After the rod is cut you can use a bench grinder or a drill & disk sander to ‘bevel’ the ends to prevent the glass fibers from fraying.

I usually wrap the ends of the rod with a bit of tape to keep the ‘splinters’ to a minimum.

Just before the AKA convention in Seattle we were fortunate to have visiting with us Curtis Marshall of Maryland. Curt is one of the many kiters that have taken this ‘hobby’ seriously and in the same light of our own George Ham has tuned his abilities to produce an incrediable assortment of fantastic kites, his lobster kite being one sample of his craftsmanship took ‘Spectator’s Choice’ at the convention.

The kite featured in this issue of Kite Flyer is another one of Curt’s kites, kites that I consider “Kites of a Lifetime” whose workmanship and quality of materials and design make them kites that will easily last for years to come.

I call this kite :a “MARSHALL-TAYLOR DELTA-CONYNE” which is a combination of a delta kite and the cells of a Conyne kite. (I believe that Hod Taylor, who Tom Henry had met in Flordia, had developed the concept of putting the two types of kites together and that Curtis had refined the design to the kite he calls the M-12 and the M-9. unfortunately I am not 100% clear of origins of the design and apologize in advance if in error.) At any rate the kite is something to behold. It had won top honors at the Smithsonian Kite Festival held in May of 1980, in the Senior Catagory for: Beauty, Flyability, Stability and orginality of design.

It is easy to understand why the kite is an award winner when considering the meticulous craftsmanship and innovative design of each of the kite parts. Curtis called the kites he showed me simply M-12 and M-9.

I believe him to mean the “Marshall 12 ft. and the Marshall 9 ft.” but I am not sure. I base this assumption on the fact that he is using a module of 4 feet and 3 feet in the respective kites mentioned. Each of the kites are modularly designed with standard set

of parts to be connected: 17 spar sections, 11 spar connectors, 4 end caps and two ball and socket joints and the kite cover. The section modules are made of 1″ diameter 6061 T – 6 aluminum tubing. The connectors are solid bar aluminum that is stepped to fit into the aluminum tube, Nylon that is machined is used for end caps and ball joints. This is not a simple kite. (You don’t have to use the materials that Curtis uses, unless you have a complete machine shop in your basement and a variety of alum. tubing at your disposal.)

The spars are made up of either 2 or 3 unit pieces. The cross spar is made using two different wall thickness of pipe. The section in the middle being slightly thicker wall for stiffness.

The leading edge spar is of two units and is enclosed in a sleeve providing the the necessary compression to keep the spar from falling apart.

The longerons and wing spars are in similar pockets at their respective locations. Nylon cap pieces are sewn into the sleeves to “Keep” the spar from falling out, these are some what adjustable for tightening up the kite cover.

The “piece de resistance” is the cross spar coupling to the wing spar. This occurs at the joint connection of the unit pieces of the wing spar and the end of the cross spar. This connection relies only on the fact that apples fall to the ground for its reason for staying together which is still a mystery to me after Curtis tried to explain the principles to me one evening. Evidently the idea works as the kites fly beautifully.

Thank you Curtis for sharing your kite with us.

CLOSE ENCOUNTERS WITH THE TETRA KIND

CLOSE ENCOUNTERS WITH THE TETRA KIND

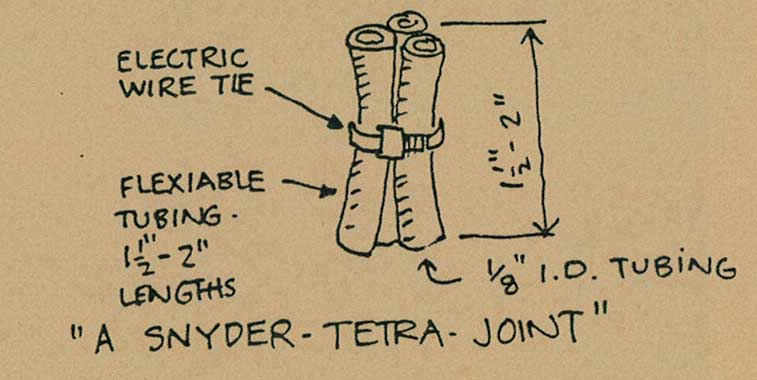

While up at the AKA convention I happened upon Mark Snyder a native of Seattle and quite a talented kite maker. He was experimenting with several of Carl Brewer’s airplane style kites (which fly great in no wind) and later brought out a beautiful Tetrahedron kite made out of about 20 or 30 cells. What is unique about this 1/8″ dowel and mylar sail kite is that it collaspes down into a relatively transportable size. Something that even the “industry” has not been able to achieve successfully.

The basis of Mark’s design is a node made of flexiable tubing and electronic wire ties. The number of lengths of tubing is determined by the number of connections necessary. I think the maximum needed is 12 which would be made using 6 lengths of tubing tied in the middle with a wire tie.

The wire ties are the smallest ones available at the electronic supply house. They look like little belts that can be tightened but not loosened.

The kite can be collasped for storage or transportation in a matter of minutes after the ‘system’ of break down is established. (This is just what Dale Vanderhoof needs for his Giant Tetra which he hauls around in two vans when he travels with it.)

The break down system is simply removinc the spar (one end only) of the tetra module that is not connected to the sail areas.

Mark’s cells were approx. 8″ on a side. The cell covering was mylar secured with transparent tape.

With a systeMatic approach to dis-assembly, the kite will “accordian” itself into a tidy package. Because of the flexiability of the tubing and the solidness of the dowell the kite can hold up to numerous assembly procedures with little damage.

HOW DO YOU SPELL RELIEF?

The first Kite Dinner of 1981 was hosted by Tom and Carol Henry on January 3rd at their apartment overlooking one of the happier hillsideq,in the City. Marty Dowling drove up from San Jose, Paul and Candy Walker and their two children, Layle and Ryan, came in from Palo Alto. George and Mari$n Ham were there as was your ed-itor. In addition to a splen-did dinner, there was animated discussion about some AKA mat-ters that will be detailed in a later issue of this newsletter, excellant slides taken by George Ham of the Edmond’s Community College giant kite in Seattle as well as slides that the editor took on the Japanese Kite Fest-ival Tour in the Spring of 1980. Fine food, flowing beverages and coloful kiting conversation filled the evening. This Cub Reporter, Stan Seifried, cer-tainly is looking forward to another such evening.

By way of standard reference–KITE FLYER NEWS is available six times a year (weather permitting) at the minimal cost of a trip to Doggie Diner–$5.00 a shot. Send all money, trading stamps or gold bars to 861 Clara Drive, Palo Alto, CA 94303.