Copyright © 1981 by Guy D. Aydlett

Dear Kiteflier:

HORNBEAM, our sled-kite that we des-cribed in the January (Volume 1, No. 2) DATA-LETTER, continues to attract good comments from talented kite-designers. For instance, this is from Oscar Bailey, whose famous “Three Mile Island” dOta -captured 1ST PLACE in the first International Ex-position of Asymmetrical Kites (see Valerie Govig’s Kite Lines, Fall Issue, page 37): ft. . I have //lade and flown many sleds: Scott, Allison, and several of my own. The Hornbeam out-performs them congrat- ulate you for a fine design. ”

Alex Dunton has been causing craned and crickety necks in Virginia’s capital city, Richmond: he flys a gaggle of Siamesed, or attached, Hornbeams.

Ebullient Warren O. “Stormy” Weathers sent us his own version of an attenuated center-section sled folded in a standard #10 business-size envelope. It flys!

Other subscribers: What have you done?

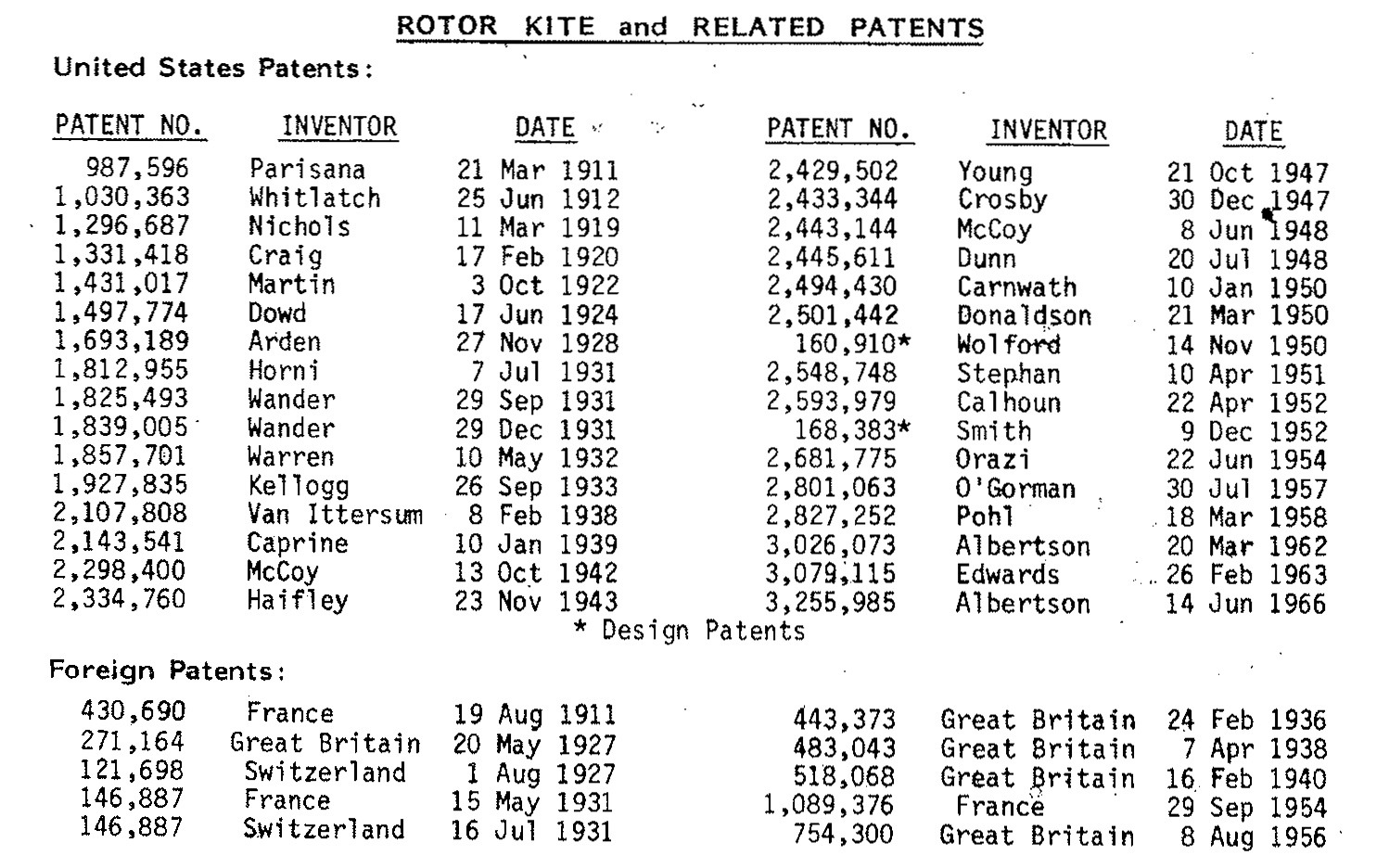

Below is a corrected and enlarged list of patents that our rotor-kite aficionados should enjoy studying. Remember that DATA-LETTER No. 2 told how patents can be ordered.

KNOTS

Scouts, seamen , and the saltiest of all salts, the landbound power squadron ad-miral, know all about knots and related en-tanglements. Kitefliers, balloonists, and airplane pilots should know about as much; but they often neglect basic knot-tying skills that prevent the loss of cherished flight-hardwares, lives, limbs, properties, and square feet of precious hides. We were reminded of our own faulty skills recently when we purchased rope and line in packets that included excellent knot-diagrams and sound advice on the use of knots and the care that should be accorded to ropes and lines. The manufacturer, Lehigh Cordage of Allentown, Pennsylvania has very kindly given us permission to reproduce the knot diagrams and to pass on the good advice that is published in the brochure: “Knots, Hitches, and Splices.” First , the advice:

CONSULT THE MANUFACTURER BEFORE USING ROPE [OR LINE]

IF PERSONAL SAFETY OR POSSIBLE DAMAGE TO PROPERTY IS INVOLVED

AVOID USING LINE THAT SHOWS SIGNS OF AGING OR WEAR.

DO NOT EXCEED THE SAFE WORKING LOAD:

8% to 14% of the tensile strength.

AVOID SUDDEN STRESSES—Shock loads can exceed breaking strength.

AVOID ABRASION—Worn line is weakened.

AVOID KINKS AND SHARP ANGLES—Line is weakened at these points.

AVOID CHEMICALS—Natural fiber lines are severely damaged by chemicals.

(For added safety , keep all lines free of chemicals.)

AVOID PROLONGED EXPOSURE TO DIRECT SUNLIGHT—

Nylon , poly , and polyester lines are weakened by prolonged exposure to the ultra-violet rays of sunlight.

KEEP LINE CLEAN—Wash with clean water to maintain longer life and maximum strength.

STORE LINE PROPERLY—In a clean environment that is free of direct sunlight , heat , and dampness.

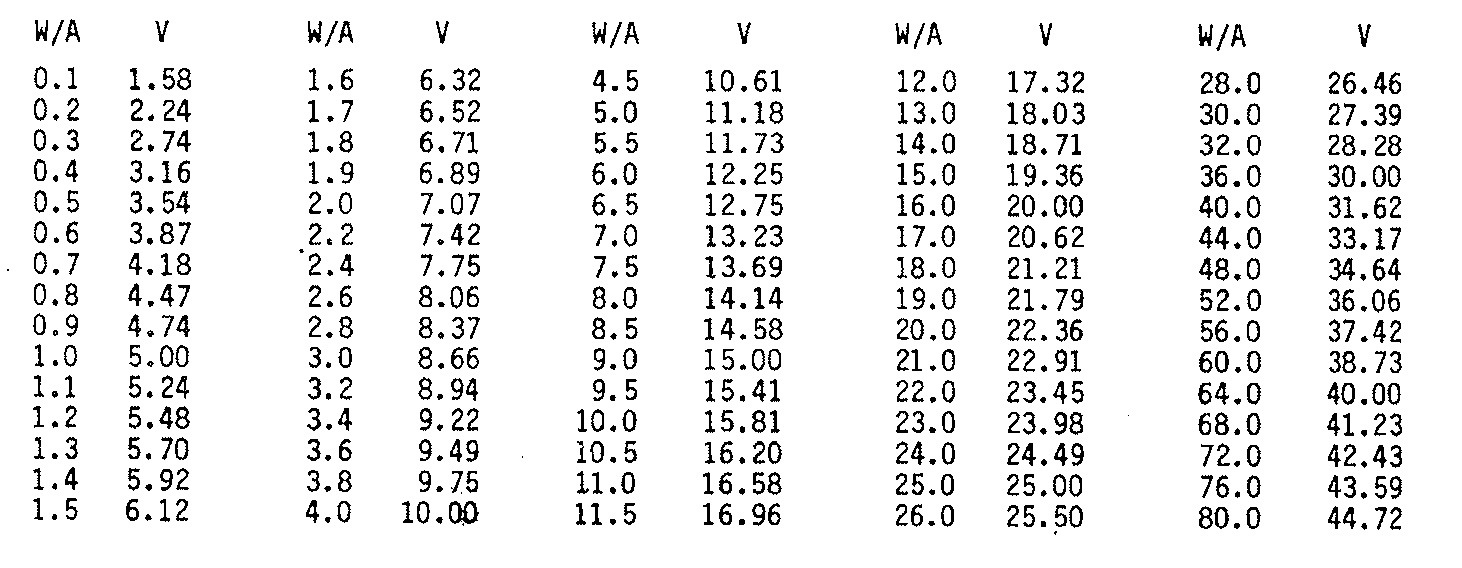

WEIGHT /AREA vs WIND VELOCITY TABLE

Did you ever wonder how much wind vel-ocity a newly created kite would need to fly? Did you ever wish for a simple formula -a rule-of-thumb-that would provide the information? If so, how about trying this:

V = 5(W/A)

Where:

V = Wind. Velocity in miles per hour

W = Kite Weight in ounces

A = Kite Area in square feet

Too complicated? Then use the table that is shown below. Just weigh your kite in ounces and divide that weight by the kite area in square feet. Find that value in the table under a W/A column; the “V” value paired with it is the minimum wind velocity in miles per hour that will sustain your kite.

Career aerodynamaticks will readily rec-ognize the procedure that was used to put our formula into action; some may even de¬duce that we used a lift coefficient of 0.997 for kites. For conventional lifting surfaces, that coefficient is acceptable as an average. (Anyone who has a purse fatter than his prudence may send one dollar and a SASE to Hornbeam, cio PMAF, for an explanation of the derivation of our magical formula.)

SANJO ROKKAKU

The Piney Mountain Air Force version of this attractive Japanese kite flys as stead¬ily as if it were stitched to the welkin. It is traditional, we understand, to make this kite with spars flexible enough to permit the wind pressure to effect the bowing and pocketing that are vital for its good tailless stability ; but slender spars limit the wind range to light or moderate velocities. To extend the useful wind range, we chose to use stouter spars and bowstrings to estab¬lish the necessary dihedral and pocketing.

Our drawing shows the kite dimensions in modules, a convenience that permits a kitemaker to use any dimensional system that suits his taste; he merely multiplies modular dimensions by any preferred unit of measurement. Our designer used 9.5″ for his module , because we had on hand a number of 25″ x 38″ sheets of 5-mil Tyveke that permitted us to employ two sheets to make a 38″ x 47.5″ canopy. The material used in our kite was Type 10. Type 14 is a better-draping material, but our kite flew well enough to win two of the three adult= category prizes—handsome Jefferson cups—in Virginia’s Ash Lawn Kite Festival at the home of President Monroe, 8 April 1980.

We used poplar (tulip wood) sticks; the 1/8″ x 1/2″ longeron was glued to the can-opy; the 1/8″ x 3/8″ spars were slipped through #8 brass split-rings that were lo-cated at the bridle attachment positions, where small doubling patches are glued. Each doubling patch was punched with a pair of small holes through which each ring was threaded. The outboard corners of the canopy were tied to the spar-ends before the spars were bowed for flight.

As made, the kite weighed 4.25 ounces; had an area of 10.03 square feet. The area loading, W /A, was 0.42 ounces per square foot. (Our table on page 3 shows that the kite needs a wind velocity minimum of about 3.24 miles per hour to fly.)

The Sanjo Rokkaku is a natural billboard or artist’s canvas; do as the Japanese did: Color the kite with a grotesque face—or decorate it with a saintly portrait of your beloved mother-in-law.

SUPPORT LOW-VELOCITY FLIGHT RESEARCH: Subscribe to the Monthly DATA-LETTER

By First Class Mail in the U.S.A. : $7.50 per year, or 75′ per copy

Send check or money order (no cash) to

Guy D. Aydlett Box 7304

Charlottesville, VA 22906